Indice dei contenuti

ToggleL’Industrial IoT (IIoT) sta rivoluzionando il modo in cui le imprese manifatturiere e industriali affrontano la produzione, la gestione degli impianti e l’ottimizzazione dei processi. Dall’integrazione di macchinari intelligenti fino all’analisi predittiva, l’Industrial IoT rappresenta uno dei pilastri dell’Industria 4.0, portando con sé nuove opportunità per imprenditori, sistemisti IT e Operations Manager. In questo articolo vedremo cos’è l’Industrial IoT, come si differenzia dall’IoT consumer, quali vantaggi offre e come AzzurroDigitale supporta le imprese in questo percorso.

What is Industrial IoT

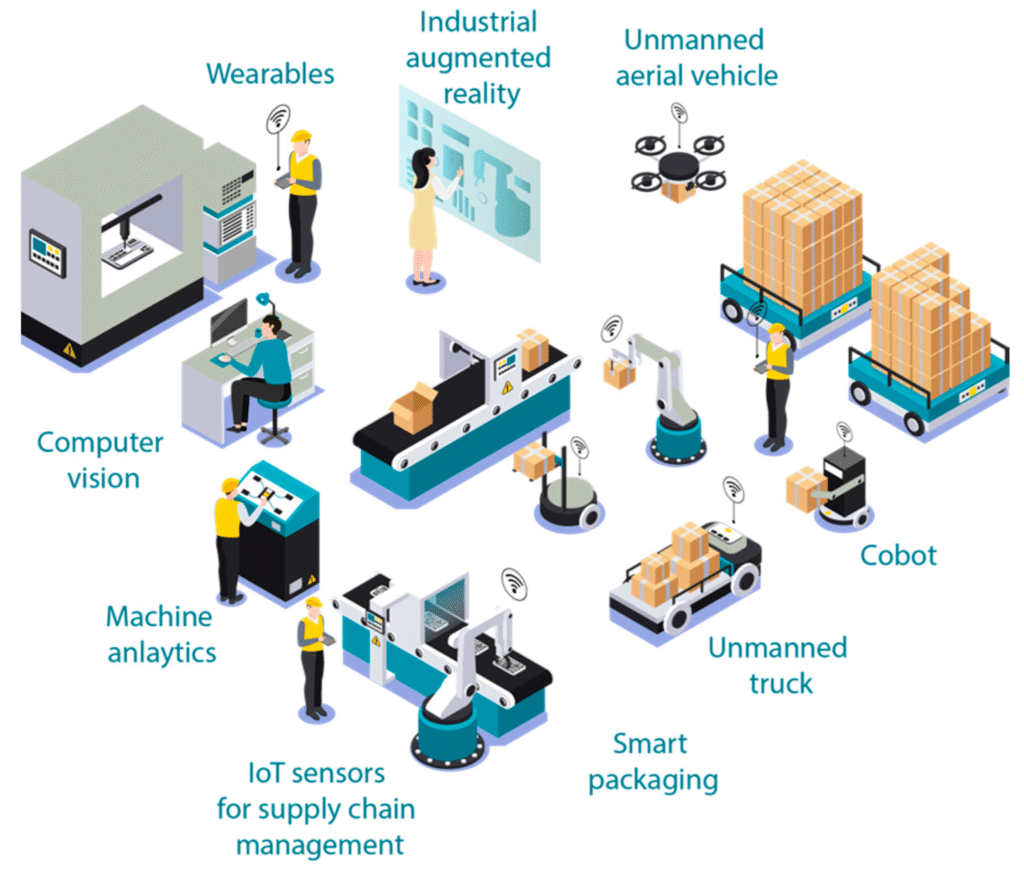

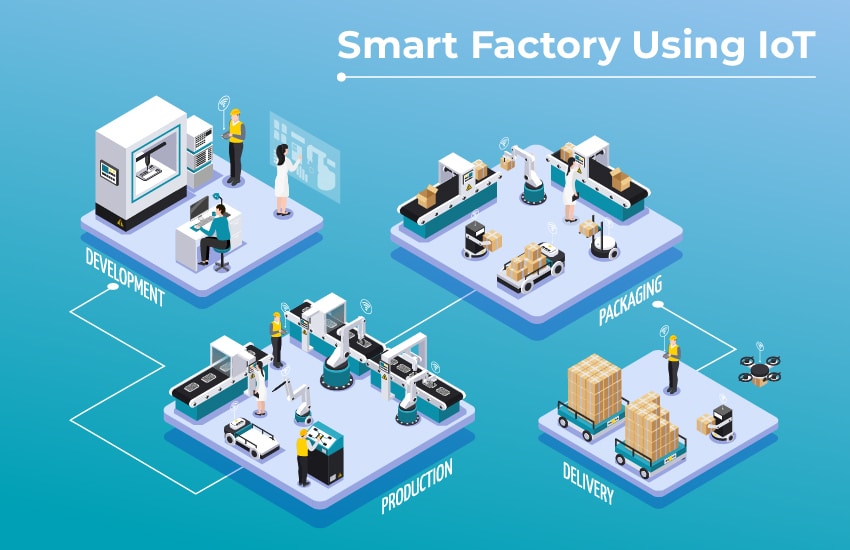

Industrial IoT extends the principles of the Internet of Things to the industrial sector. It involves equipping machinery, systems, and infrastructure with sensors, connected devices, and intelligent software to collect, process, and share data in real time. This allows companies to continuously monitor the status of production lines, prevent failures, reduce waste, and optimize performance.

A practical example of Industrial IoT is the use of sensors on machinery to monitor vibrations, temperature, or energy consumption, reporting any anomalies before they result in costly plant downtime.

IoT e Industrial IoT

It’s important to distinguish consumer IoT from Industrial IoT. Traditional IoT involves everyday devices such as smart appliances, connected cars, or wearable devices. Industrial IoT, on the other hand, applies to complex manufacturing and industrial contexts, where the stakes are much higher: efficiency, product quality, personal safety, and business continuity.

As the Internet of Things Observatory explains, Industrial IoT combines connected devices, control systems (SCADA, PLC), cloud platforms, and advanced analytics algorithms to support data-driven decisions.

The evolution of Industrial IoT

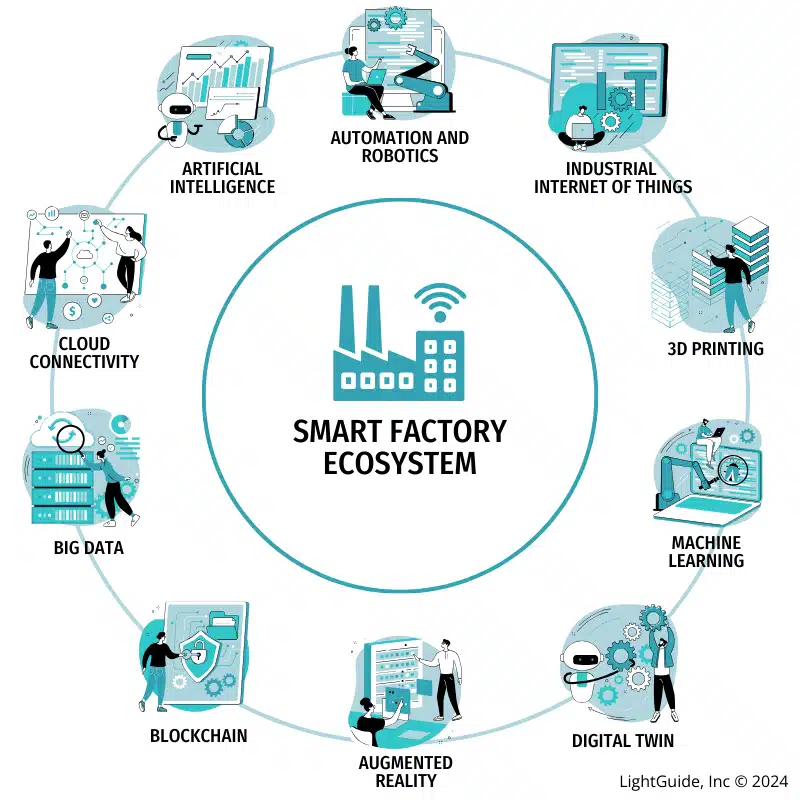

Industrial IoT has evolved rapidly in recent years. The adoption of smart sensors and 5G connections has made it possible to collect large volumes of low-latency data, integrating it with artificial intelligence systems to gain valuable insights. From simple data collection, we have moved on to predictive maintenance, proactive resource management, and the creation of digital models (digital twins) to simulate future scenarios. Industrial IoT, along with technologies like AI, is the backbone of smart factories.

The advantages of Industrial IoT

Greater efficiency

Implementing Industrial IoT solutions means making production processes more efficient. Machines communicate with each other and with supervisory systems, reducing downtime, waste, and manual interventions. Real-time data allows you to identify bottlenecks and take prompt action.

Cost reduction

Another major benefit is reduced operating costs. Through predictive maintenance, companies can minimize unplanned downtime, optimize energy and raw material usage, and extend the life of their equipment.

Improving product quality

Industrial IoT enables more rigorous and consistent quality control. Sensors collect data throughout the production cycle, allowing for real-time correction of any deviations from standards. This translates into less waste, fewer returns, and greater end-customer satisfaction.

Technologies complementary to the Industrial IoT

L’Industrial IoT diventa davvero potente quando si integra con altre tecnologie abilitanti. Tra queste, l’intelligenza artificiale e il machine learning giocano un ruolo cruciale: grazie a sistemi di AI, i dati raccolti dai sensori non si limitano a descrivere cosa sta accadendo in fabbrica, ma vengono analizzati per individuare schemi ricorrenti, prevedere guasti prima che si verifichino e supportare decisioni strategiche più accurate. Gli algoritmi di machine learning, infatti, imparano continuamente dal comportamento reale delle macchine, migliorando di giorno in giorno l’efficienza dei processi produttivi.

Un altro tassello fondamentale sono i software specifici come i MES (Manufacturing Execution System) e gli ERP. Questi strumenti non si limitano a registrare dati: li trasformano in azioni concrete, coordinando la produzione, la logistica e la gestione della supply chain. In pratica, collegano ogni anello della catena produttiva, creando un vero ecosistema interconnesso dove ogni dato genera valore.

In this same integration logic, the digital twin represents one of the most interesting innovations. It is a digital twin of the physical plant, updated in real time thanks to information sent by sensors. Having a virtual copy of the factory allows you to simulate alternative scenarios, test modifications without risks, and plan investments more effectively and effectively.

Finally, we can’t talk about Industrial IoT without mentioning automation and industrial robotics. Today, collaborative robots—so-called cobots—and automated production lines no longer operate in isolation, but communicate directly with IoT systems. This allows them to receive updated instructions, work synchronized, and adapt in real time to production needs, ensuring flexibility and operational continuity.

Challenges in Industrial IoT Integration

Cybersecurity

Connecting machines and devices increases vulnerabilities. It’s essential to invest in cybersecurity solutions to protect sensitive data and prevent cyberattacks.

Integration with existing systems

Many manufacturing plants use outdated machinery that isn’t natively IoT-ready. Upgrading the infrastructure and integrating new technologies can require significant investments and careful planning.

Need for staff training

To fully leverage the benefits of Industrial IoT, it’s essential that manufacturing and IT teams are properly trained. Specific skills are needed to manage new systems, analyze data, and make decisions based on the insights generated.

High initial cost

The initial investment in sensors, IoT platforms, and infrastructure can be a barrier for SMEs. However, the returns in terms of efficiency and savings pay off in the medium to long term.

Industrial IoT e AzzurroDigitale

In AzzurroDigitale, crediamo che l’Industrial IoT sia la chiave per rendere le fabbriche non solo più efficienti, ma anche più resilienti, collaborative e data-driven.

Per questo abbiamo sviluppato MATIX: una soluzione IoT innovativa progettata per il monitoraggio predittivo e l’ottimizzazione delle attrezzature industriali, con focus specifico su molds & dies (stampi e utensili).

Con MATIX, le imprese manifatturiere possono:

- Increase asset tooling efficiency by 20% through advanced process and performance analytics.

- Reduce downtime by 40% by constantly monitoring asset health and taking predictive action.

- Extend asset lifecycle by 15% by planning maintenance more intelligently and reducing uncontrolled wear.

- Reduce supply chain costs by 10% through increased collaboration with supply chain partners and shared visibility into outsourced assets.

MATIX abilita il condition monitoring di stampi e utensili industriali, trasformando i dati grezzi in insight utili per la manutenzione predittiva, la gestione di fornitori esterni e l’automazione dei processi di auditing.

Grazie alla sua infrastruttura IoT, MATIX aiuta le aziende a:

- Unlock continuous operational improvement (OEE).

- Receive predictive notifications for targeted interventions.

- Monitor molds and equipment in real time even if they are outsourced.

- Automate quality control and auditing.

Vuoi rivoluzionare la gestione dei tuoi stampi e utensili?

Scopri come MATIX può aiutarti a migliorare la performance, prevedere i guasti e monitorare la supply chain.