ONLINE EVENT

Galvanica Digitale Masterclass

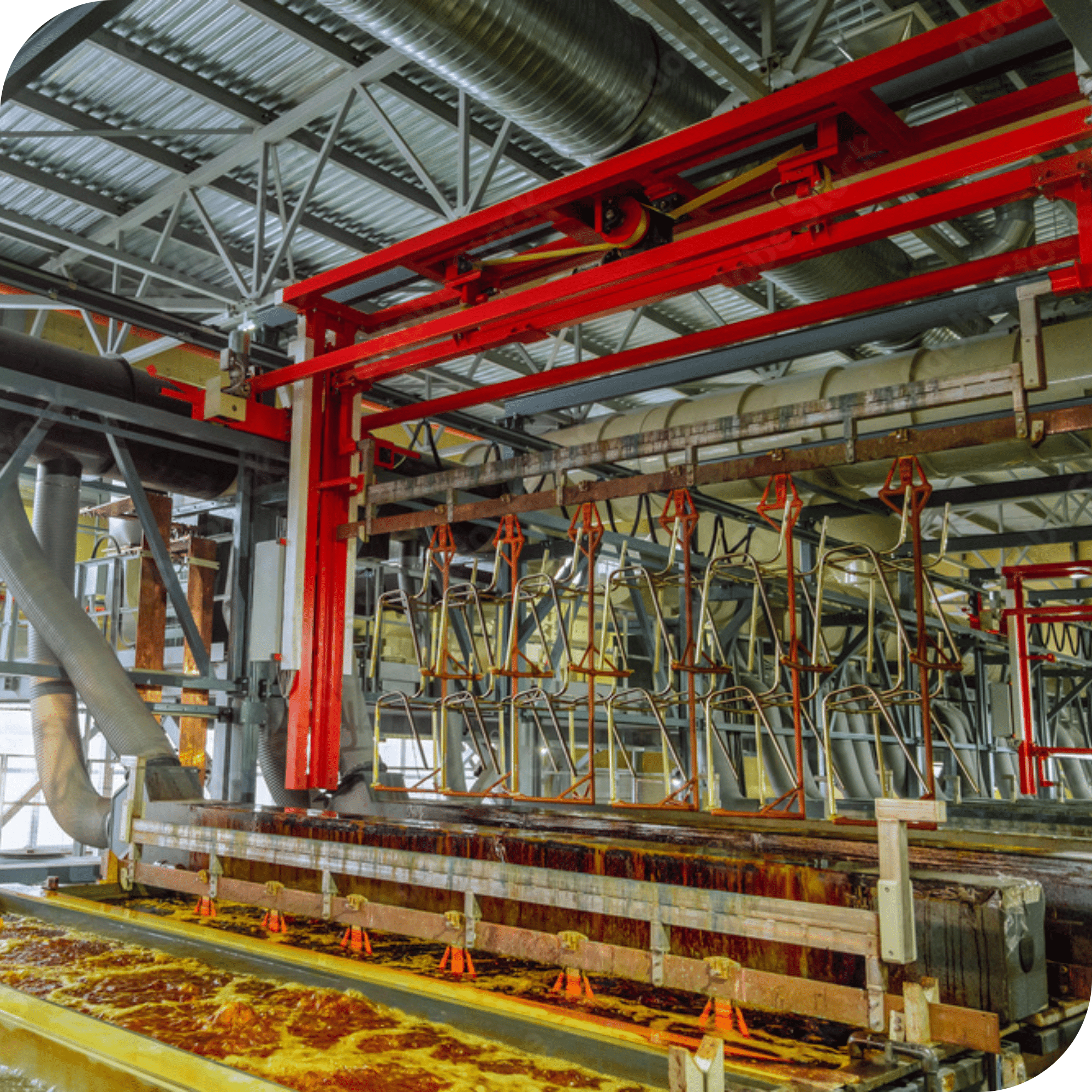

A series of online events designed to explore the opportunities of electroplating applied to galvanic plants.

A practical and vertical path that addresses the most pressing needs of the sector: from the traceability of maintenance required by the supply chain, to the timely reporting of anomalies, to the reduction of waste and the elimination of paper thanks to the digital collection of process data.

The goal? Offer concrete tools to understand how to make a electroplating plant more efficient, controlled and connected.

Calendar

Discover the power of Digital applied to Electroplating

/ 1

How can AI revolutionize electroplating processes?

When?

📆 May 22nd

⏰ 12:00 – 12:45

🌍 Google Meet

Speakers

Jacopo Pertile CEO and Founder @ AzzurroDigitale

Sara Muzzolon Digital Consultant @ AzzurroDigitale

/ 2

Galvanica Digitale: the case of Dradura Italia

When?

📆 June 26th

⏰ 12:00 – 12:45

🌍 Google Meet

Speakers

Jacopo Pertile CEO and Founder @ AzzurroDigitale

Matteo Zanandrea CEO @ Dradura Italia

Why participate?

Reduce waste and operating costs with real-time process monitoring and automatic plant data collection.

Manage maintenance and quality digitally and centrally, abandoning Excel sheets and paper documents.

Detect anomalies and malfunctions promptly, preventing plant downtime and optimizing production continuity.

Comply with increasingly stringent customer and supply chain standards in terms of traceability, quality control and data transparency.

The themes

How can AI revolutionize electroplating processes?

Galvanica Digitale: the case of Dradura Italia

Want to know more?

THE ARTICLE

Digital Galvanica 4.0: Dradura focuses on digitalization and sustainability

The project was born from a collaboration between AzzurroDigitale and the University of Padua, and received co-financing through the IRISS Call, promoted by SMACT Competence Center.

THE CASE STUDY

The GD 4.0 implementation project in Dradura Italia

The introduction of GD 4.0 in the Dradura Italia plants has brought enormous benefits, such as the reduction of waste and the increase in operational efficiency (by 80%).

THE TECHNOLOGY

The platform for monitoring electroplating processes

Electroplating processes are complex, often unstable and subject to human error. Galvanica Digitale was designed to simplify all this, guiding operators in their daily activities.