Komatsu is a Japanese multinational founded in 1923 in Komatsu City, specializing in the production of earthmoving machinery and solutions for construction and mining. With over a century of history, the company is recognized globally for its innovation, quality, and reliability. It has been present in Italy since 1990, when it acquired the Veneto-based company FAI, gradually transforming it from a small, family-run business into a strategic subsidiary of the multinational group.

SCROLL

Overcoming the limitations of paper-based and manual management of human resources data.

Integrate data from different company information systems to gain a single, up-to-date, real-time view.

Make information on each resource's training, skills, and limitations immediately available to facilitate departmental allocation.

Equip managers with simple, intuitive tools to organize teams quickly and effectively.

Avoid assigning inadequately trained personnel or personnel lacking the skills required for a specific job.

To address the challenges of asset management, Komatsu chose to introduce an AWMS, with the aim of transforming a previously fragmented and manual process into a digital, integrated and transparent model.

The new system represented a true paradigm shift. All the information that was previously stored in paper documents or accessible only to a select few managers—attendance, skills, training status, and employee limitations—has been gathered into a single digital environment and made available in real time.

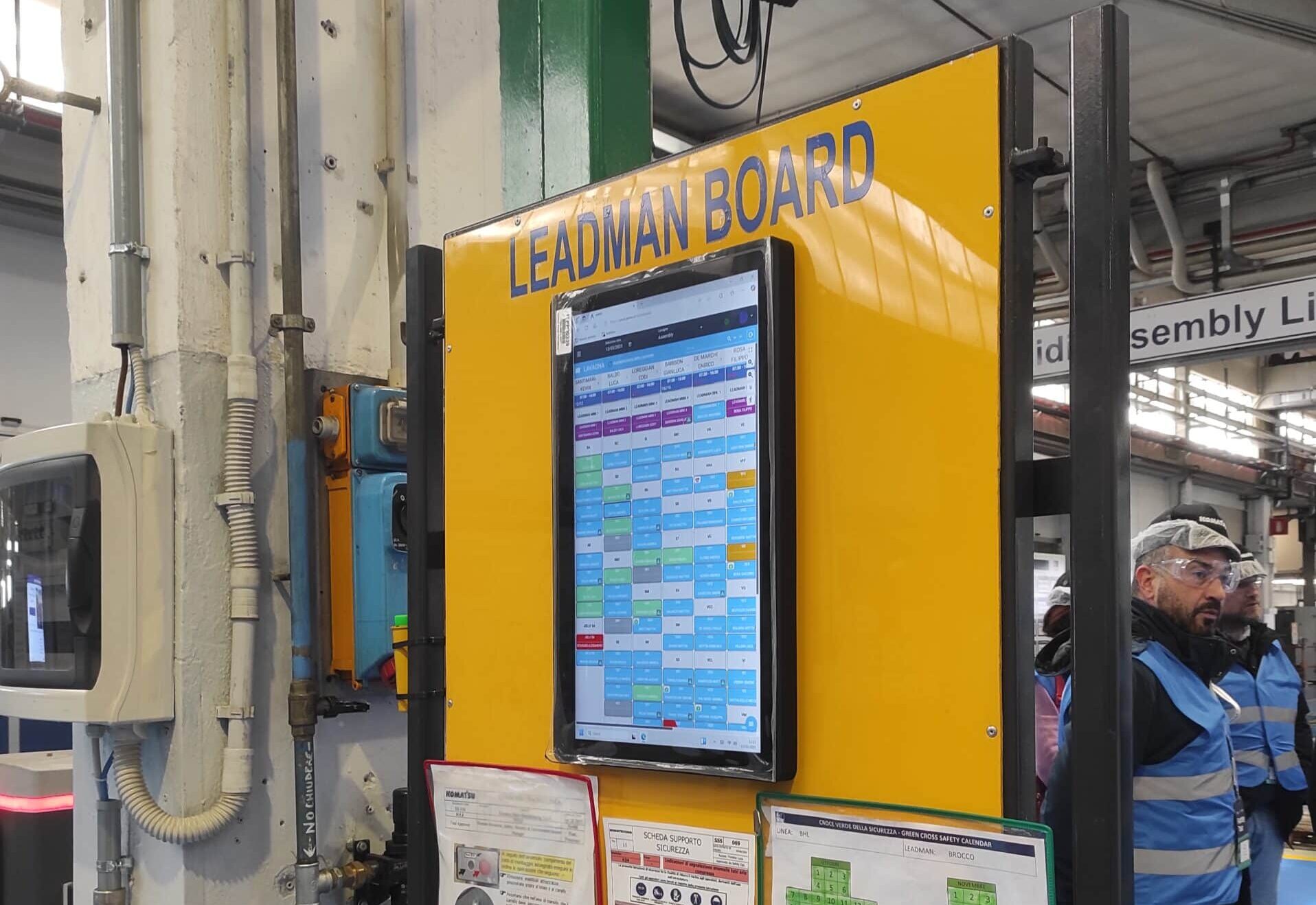

This new visibility has allowed the installation of panel monitors directly on the assembly line to support team leaders. Thanks to these tools, managers can now organize their teams immediately, based on up-to-date and reliable data. In the event of unexpected absences, the system promptly reports the critical situation and allows for rapid and effective reassignment, ensuring production continuity.

The adoption of AWMS also introduced a fundamental principle: each resource is allocated only if they possess the appropriate skills and training. This minimizes errors and operational risks, ensuring consistent quality throughout the entire production chain.

The solution therefore did not simply bring efficiency, but made the organization more agile, responsive, and above all, focused on valorizing people and their skills, strengthening Komatsu's commitment to innovation and customer centricity.

The introduction of AWMS has generated immediate and tangible benefits for Komatsu, transforming day-to-day production management.

Thanks to the availability of centralized, real-time data, team leaders can now make quick and accurate decisions, organizing teams with previously unimaginable clarity. This has meant fewer interruptions, less uncertainty, and the ability to react promptly to any unexpected event, from unexpected absences to the need to fill new positions on the line.

The company has seen a significant reduction in errors in resource allocation: each person is assigned to a role appropriate to their skills, with a direct impact on work quality and safety. At the same time, greater process transparency has made collaboration between departments more fluid, fostering an organizational climate based on trust and accountability.

In addition to operational efficiency, AWMS has helped strengthen the customer-oriented approach that has always guided Komatsu: leaner and more streamlined production translates into better service and products that consistently meet the high standards required by the market.

Ultimately, the project not only brought about a technical improvement, but also represented a decisive step towards a more modern, agile production model capable of better valorizing people, the true beating heart of the company.

Thanks to the live information we can acquire from integrated systems, our team leaders can organize teams in a timely manner, avoiding errors and ensuring production continuity.

AWMS is the digital solution that allows you to plan your workforce, both in production and in the warehouse, in a simple and effective way. Thanks to AWMS, you can organize the work of operators taking into account skills, physical limitations and professional development, and always ensuring compliance with company compliance and labor law regulations (rotations, contractual limitations, mandatory rest, etc.).

Furthermore, AWMS helps you keep costs under control, highlighting the gaps between what you planned and what actually happens. It is the ideal tool to increase productivity and support the growth of your employees with job rotation and job enlargement paths.

Write to us about what you need! Together we will identify the best solution for your needs.

"*" indicates required fields

Via della Croce Rossa, 36

35129 – Padua

* Applications sent to this email will not be considered