Indice dei contenuti

ToggleFrom regulations to machine: Ritmo simplifies plastic welding configuration with an intelligent assistant

Article by Dario De Giovanni – Full-stack Developer at AzzurroDigitale

Configuring a weld has never been this simple. Ritmo introduces an intelligent chatbot that transforms a technical and complex process into a natural conversation. The AI assistant guides the operator step by step, verifies regulatory compliance, and automatically sets the correct parameters. Fewer errors, more efficiency, and a new way to “talk” to the machine.

In a company like Ritmo, specialized in the production and use of plastic welding machines, the correct configuration of parameters is a crucial phase. An error — even a minimal one — can result in scrapped parts, rework, and downtime.

Each weld must comply with a set of parameters that depend on:

- the applicable regulation (ISO, DVS, UNI, etc.),

- the pipe material,

- the thickness,

- the diameter.

Until now, operators had to consult manuals or Excel spreadsheets, trying to cross-reference technical data and regulatory rules: a lengthy process prone to human error.

Ritmo wanted to transform this complex step into a natural dialogue. The result is an intelligent chatbot, integrated directly into their configuration app, that allows the operator to “talk to the machine” in natural language — text or voice — to obtain the correct parameters in just a few seconds.

The chatbot:

- guides the user step-by-step, asking only the necessary information in the right order;

- verifies in real-time the compliance of parameters with official regulatory documents;

- explains errors or inconsistencies, suggesting valid alternatives;

- returns complete and compliant parameters, ready to be automatically set on the machine.

For Ritmo and its customers, the benefit is immediate:

- fewer errors and reduced setup times,

- more compliance and traceability,

- simplified onboarding even for less experienced operators.

In the workshop, all it takes is a phrase like:

“I need to weld two PE100 pipes, thickness 5.8 mm, diameter 110 according to ISO 21307” and the system responds with the correct parameters, ready to be applied — even vocally, thanks to audio synthesis.

HOW IT WORKS — When you ask “I want to weld two PE100 pipes, 110 mm”, the system knows what to do

Behind a natural request, a chain of analysis is activated that combines linguistic understanding, business logic, and regulatory validation.

The system is based on two main flows, designed to handle every type of interaction:

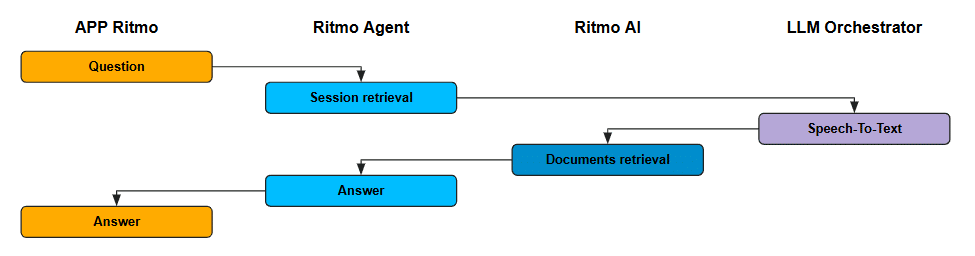

1. Informational flow

When the user asks questions like “what regulation applies to PE100?” or “what pressure is needed for ISO 21307?”, RitmoAI, the RAG (Retrieval-Augmented Generation) engine, comes into play. RitmoAI retrieves information from company documents, synthesizes it, and responds by citing sources. It’s like having an expert available who knows all the manuals and technical tables by heart.

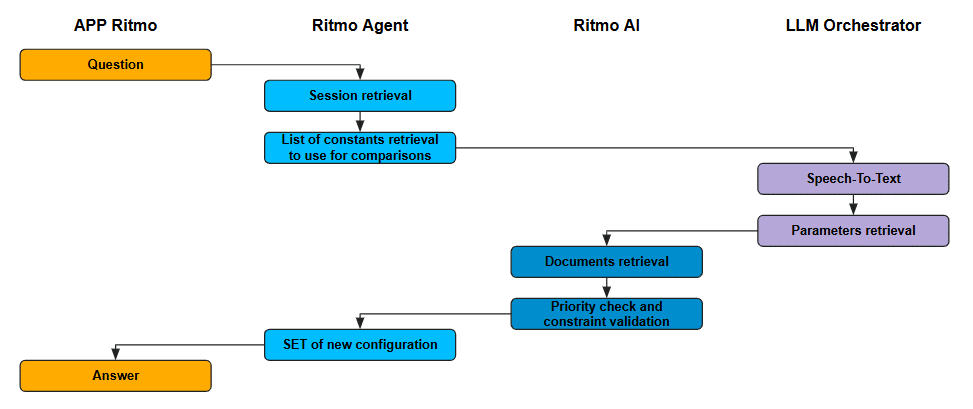

2. “Set” flow (main)

When instead the user asks to configure a weld, the operational flow comes into action:

- Phrase analysis → the LLM identifies the mentioned parameters and understands what’s missing.

- Priority check → if the regulation is missing, the system stops and asks for it; if everything is defined, it proceeds with the following steps (material, thickness, diameter).

- Constraint validation → RitmoAI queries the regulatory files to verify that the values are allowed (for example, that the thickness is compatible with the selected regulation).

- Voice handling → if the user speaks, a Speech-to-Text module transcribes the audio and the response can be returned in synthesized audio via Google Cloud Text-to-Speech.

- Structured response → the app receives the data in JSON format, along with a readable version for the operator or played back vocally.

Thanks to this logic, the chatbot doesn’t just “respond”: it guides the process, checks correctness, and adapts to situations. Even if the user provides parameters in random order or changes language, the system reorganizes the data and maintains a coherent flow.

Deep Tech for Insiders

Architecture and validation logic

The project relies on RitmoAI‘s LLM + RAG architecture, enriched with an industrial logic Agent.

Main components

- LLM Orchestrator

Interprets the request, extracts technical parameters, and manages priority rules (regulation → material → thickness → diameter). - RitmoAI (RAG Engine)

Performs semantic searches on vectorized regulatory documents and provides validation rules. - Ritmo Agent

Applies business logic, normalizes units and formats, handles edge cases (missing parameters, unmet dependencies, skipped steps). - Speech Layer Transcription and speech synthesis via Gemini and Google Cloud Text-to-Speech.

Synthetic technical flow

- Parsing & normalization of the request.

- Logic and dependency check (order, completeness, consistency).

- Regulatory validation via queries to RitmoAI.

- Structured + multimodal output (JSON, text, audio).

INFORMATION flow

SET flow

Managed Edge Cases

The system is designed to handle even the ‘imperfect’ situations typical of real-world use, always keeping the conversation coherent and productive.

Out-of-Order Parameters

If the user provides data in the wrong sequence—for example, thickness and diameter before the standard—the system recognizes, reorders, and only prompts for the missing information, without interrupting the flow.

Invalid Values

When a parameter does not comply with the limits set by the standard, the chatbot clearly explains the error and suggests compatible alternatives, preventing the operator from wasting time with trial and error.

Missing Dependencies

Some values can only be verified by knowing other parameters (e.g., thickness without the standard). In these cases, the system suspends validation and specifically asks for what is needed to proceed.

Technical Benefits

The system requires no retraining: new regulatory files can be easily added without modifying the existing model.Every answer is fully traceable, as it is always linked to the specific regulatory sources from which it originates.Thanks to its modular architecture, the solution is also highly scalable and can easily adapt to the integration of new standards or production processes.