SIAP is a company of the Carraro Group, an international leader in the production of gears and transmission systems. With a long manufacturing tradition, SIAP has evolved over the years to become a center of technological excellence, with a particular focus on the agricultural, earthmoving, and, more recently, automotive and electrical sectors.

SCROLL

Create a baseline to have a clear and up-to-date overview of production operators' skills.

Replace the memory-based management of outgoing managers, who planned shifts and allocations based on their long experience.

Manage the allocation of people based on the production mix and the daily needs of each line.

Integrate data related to physical limitations and suitability into planning processes to protect the health and well-being of workers and monitor the necessary qualifications for first aid, safety, and emergency situations in real time.

In 2021, SIAP launched a partnership with AzzurroDigitale, implementing the AWMS (Advanced Workforce Management System) to digitize skills planning and management.

The project began with a complete skill mapping: each operator was entered into the system with their own skills, authorizations, and limitations. This allowed for the creation of a true digital skill matrix, accessible to department heads and shift supervisors.

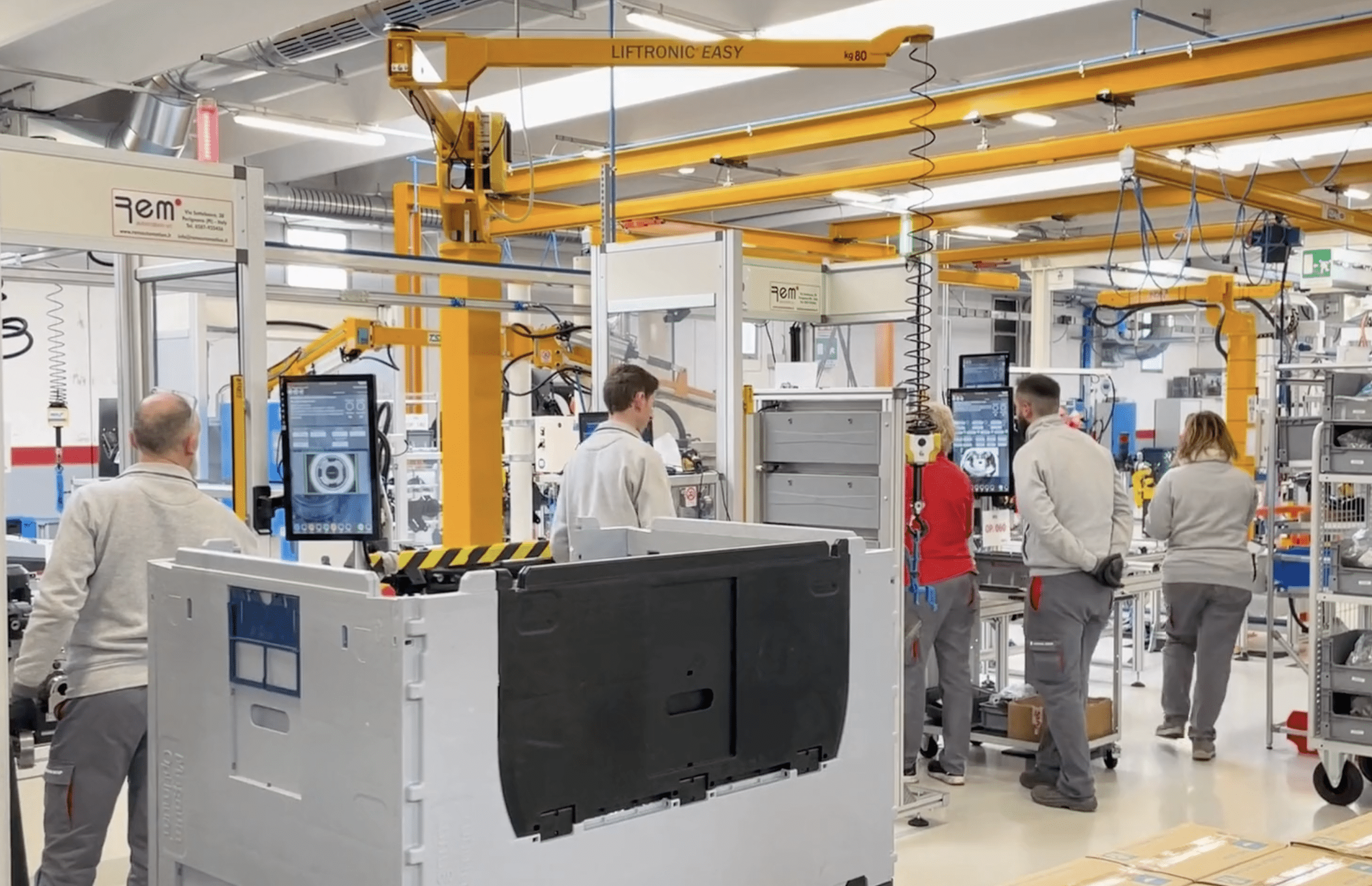

AWMS was then extended to the assembly lines, becoming a daily planning tool: saturations, assignments and loads are managed for each workstation, allowing for faster and more precise staff distribution.

Another key element was integration with safety systems (CARSAN and Q81), which monitors physical limitations, ergonomic suitability, and mandatory certifications. This ensures that each operator is assigned only to workstations compatible with their profile, safeguarding efficiency and health.

Thanks to the implementation of AWMS, SIAP has achieved significant benefits:

Efficient planning: shift managers can now allocate staff quickly, based on objective and constantly updated data.

Organizational continuity: know-how is no longer tied solely to the memory of historical managers, but structured and accessible throughout the company.

Skills development: each person is assigned to the most suitable position, promoting professional growth and maximum productivity.

Enhanced safety and ergonomics: thanks to the digital management of limitations and eligibility, operators are protected in a timely manner.

Compliance and control: real-time monitoring of mandatory certifications to ensure emergency needs are met.

In a highly automated and complex context like that of the HV plant, AWMS has proven to be a strategic tool: it has made planning more precise and transparent, helping the company maintain high standards of productivity, safety, and employee development.

With the introduction of AWMS, we've completely redefined our skills, creating a clear and comprehensive operator mapping. This now allows us to support department managers in their daily planning, allocating staff based on the production mix and their skills, while ensuring efficiency, safety, and ergonomics.

AWMS is the digital solution that allows you to plan your workforce, both in production and in the warehouse, in a simple and effective way. Thanks to AWMS, you can organize the work of operators taking into account skills, physical limitations and professional development, and always ensuring compliance with company compliance and labor law regulations (rotations, contractual limitations, mandatory rest, etc.).

Furthermore, AWMS helps you keep costs under control, highlighting the gaps between what you planned and what actually happens. It is the ideal tool to increase productivity and support the growth of your employees with job rotation and job enlargement paths.

Write to us about what you need! Together we will identify the best solution for your needs.

"*" indicates required fields

Via della Croce Rossa, 36

35129 – Padua

* Applications sent to this email will not be considered